NEWS

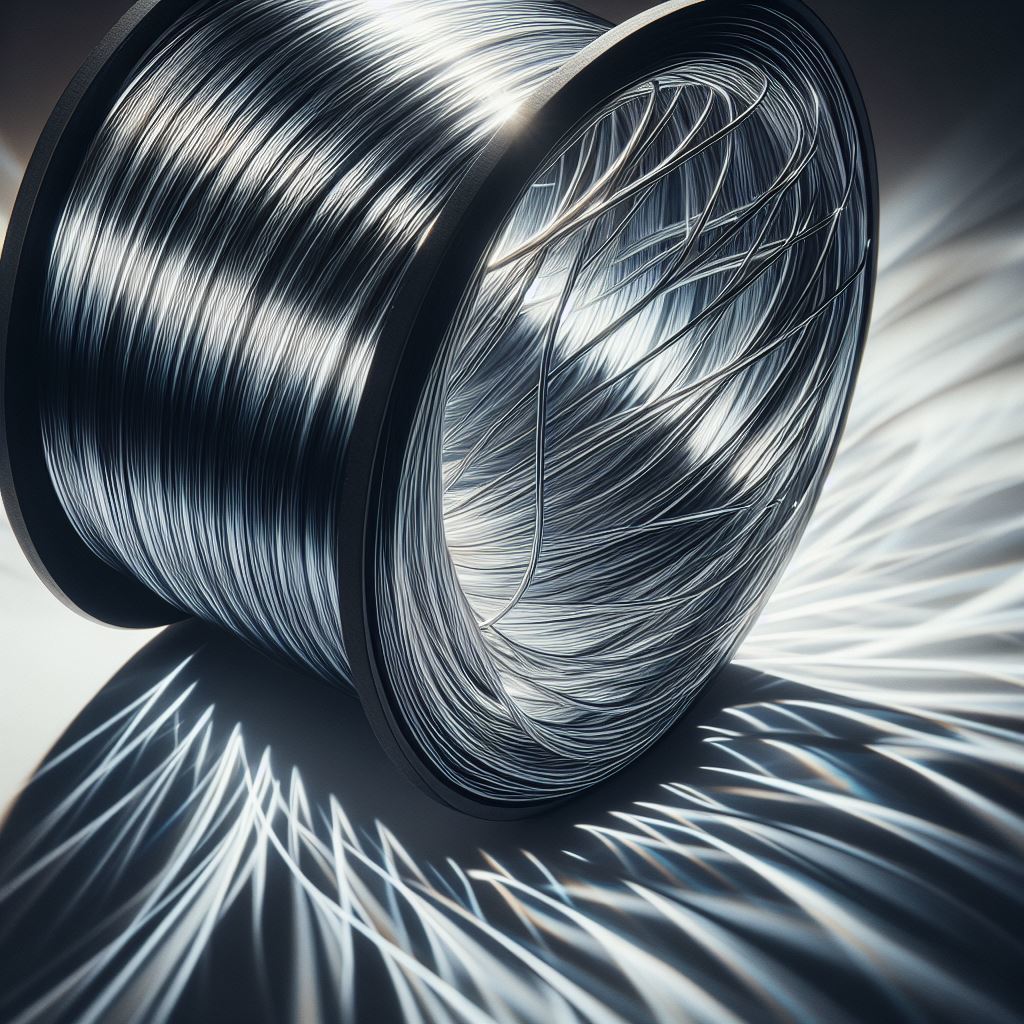

Methods to Maintain the Luster of Silver-Plated Copper Wire

Release time:

2023-11-23 11:37

Methods to Maintain the Luster of Silver-Plated Copper Wire

Compared to pure copper wire, silver-plated copper wire exhibits significantly improved conductivity, thermal conductivity, and corrosion resistance. Conducting a secondary silver plating on high-quality oxygen-free copper yields an enhanced version of silver-plated copper wire. This type of wire finds extensive applications in the fields of electronics, aerospace, and military. The only drawback is that, if not handled properly, the luster of silver-plated copper wire can diminish rapidly.

How to Better Preserve the Luster of Silver-Plated Copper Wire:

1. Increase Silver Plating Thickness and Density:

- Enhancing the thickness of the silver-plated layer and its density can effectively delay the discoloration of the entire plated area. Although this may lead to increased production costs due to thicker plating, it helps control the overall defect rate, resulting in a more cost-effective solution.

2. Optimal Storage Conditions:

- If possible, store the finished silver-plated copper wire in a constant temperature, relatively dry, and dark environment. This practice reduces the exposure time of the wire to light and moisture in the air, thus extending the time before discoloration occurs.

3. Attention to Detail During Silver Plating:

- Wear gloves during the silver plating process to avoid direct contact with the wire. Manufacturers should regularly inspect the cleanliness of the molds used in production to minimize the risk of scratching the plated surface.

For already completed silver-plated copper wire, aside from implementing the mentioned methods to slow down discoloration, using soft, environmentally friendly, non-halogen materials for packaging semi-finished silver-plated copper wire can effectively isolate it from the surrounding air and decelerate the discoloration of the silver-plated layer.

News