Enameled silver plated copper wire

Silver plated enameled copper wire is the main type of winding wire, which consists of conductor and insulating layer. After annealing and softening, the bare line is painted and baked.They all have four major properties: mechanical properties, chemical properties, electrical properties and thermal properties.

Insulation-enameled name:polyurethane enameled wire

Thermal level℃ (working time 2,000h):130

Code name:UEW

GB Code:QA

ANSI.TYPE:MW75C

Keywords:

Category:

Enameled silver plated copper wire

MESSAGE

DESCRIPTION

Silver plated enameled copper wire is a type of electrical wire where copper wire is coated with a thin layer of silver and then insulated with enamel. This combination provides good electrical conductivity from the silver and insulation to prevent short circuits from the enamel. It's commonly used in applications where both electrical performance and insulation are critical, such as in transformers and coils.

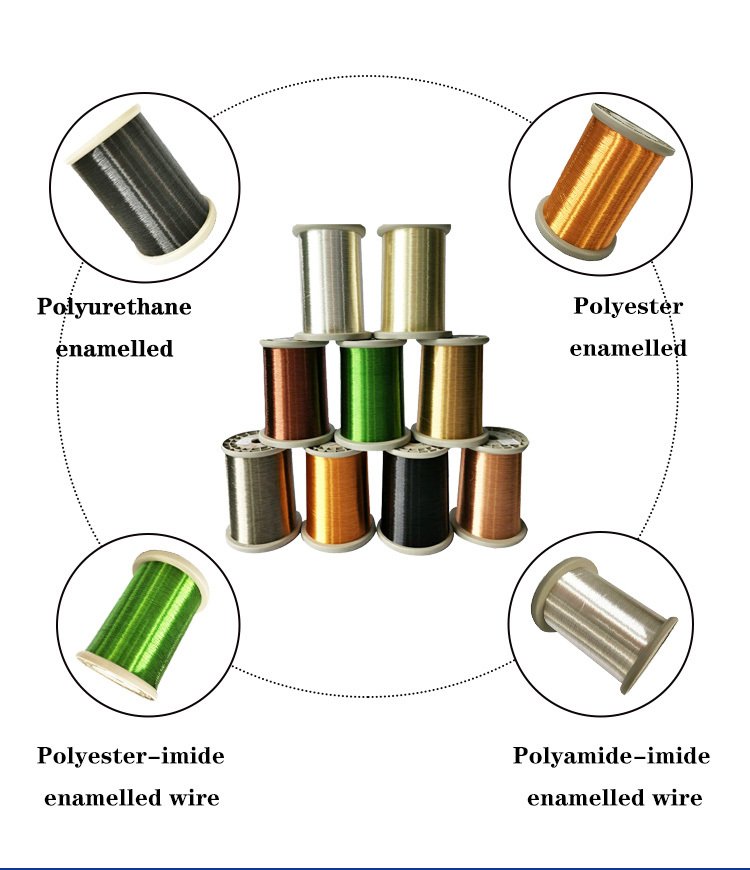

Type of Insulation

Specification

Materials and product standards

Resistivity

Dimensions and Deviations

Mechanical Behavior

Packing and delivery

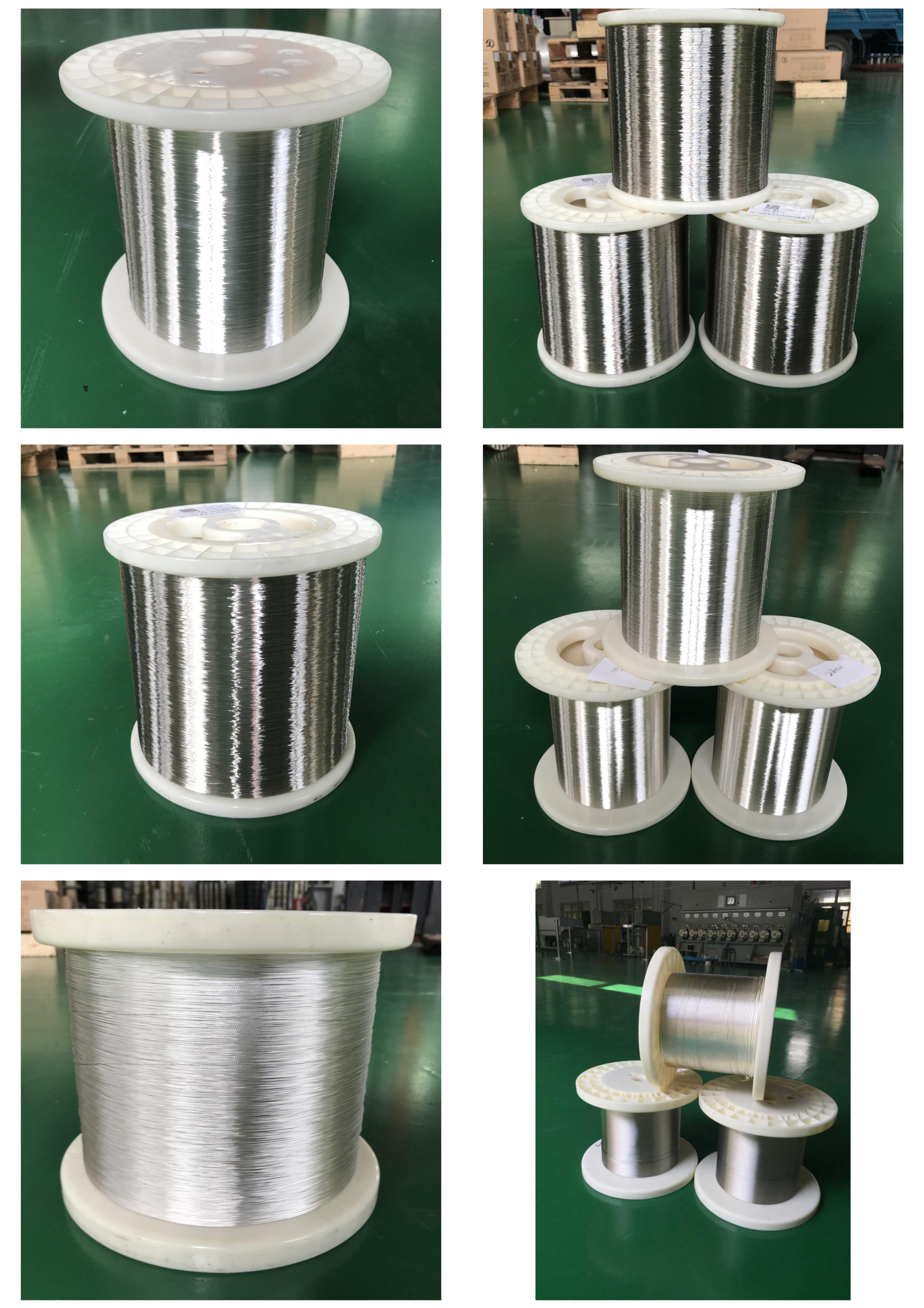

1.The mono-filament and its winch are supplied in plates, and then packed and delivered in boxes after proper packaging with Kraft paper and packaging film. The small size disc is fixed by custom foam, and the large size plastic rubber disk or iron disk is fixed by custom wooden frame.

2.The mono-filament and its strand are evenly wound on the wire shaft, the wire arrangement is not pressed, the wire head is fixed, and the outermost side of the wire is kept at a certain distance from the edge of the disk, so as to avoid collision in the course of transportation.

Coating

1. Coating evenly,good continuity, strong adhesion.

2. The surface of the coating is smooth and continuous without harmful defects such as silvery burr mechanical damage.

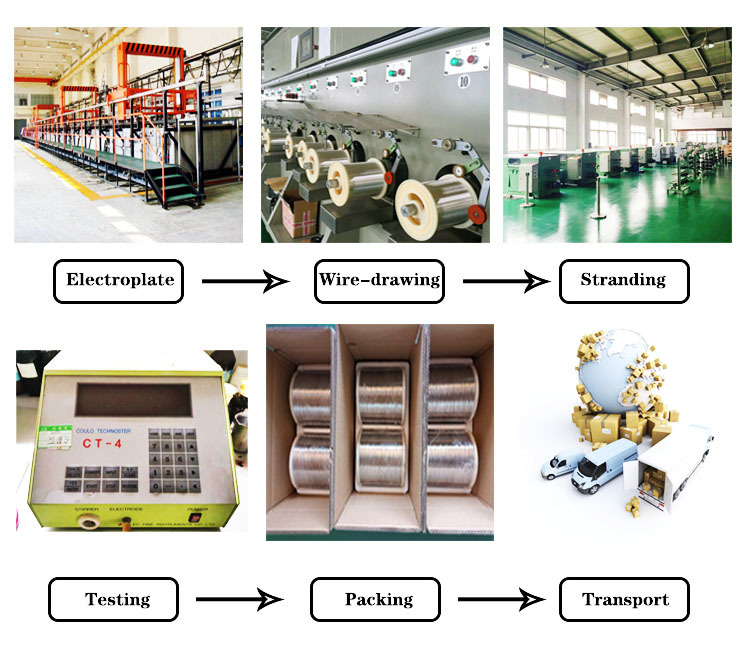

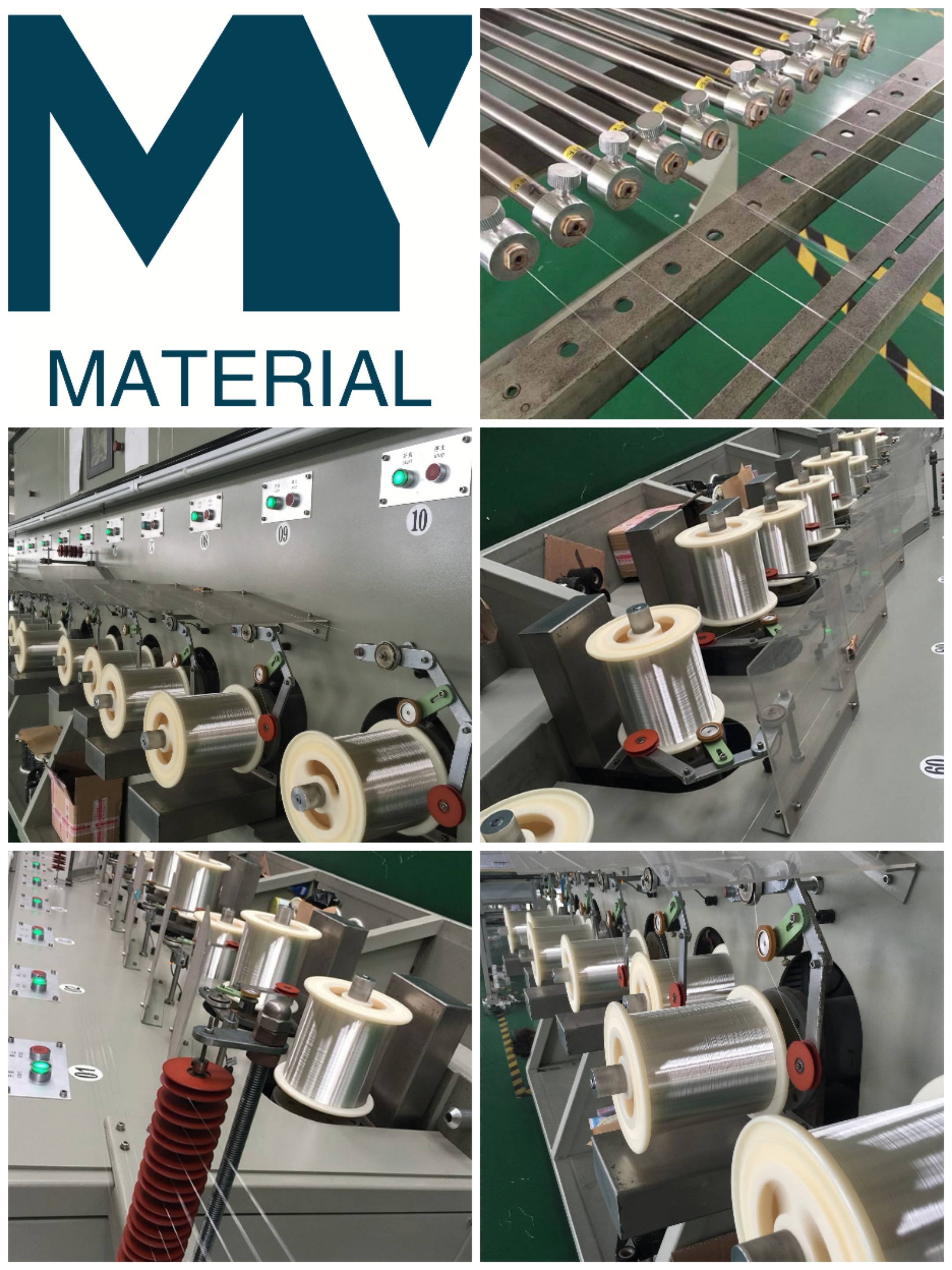

Product Processes

Enameled wire is a major type of winding wire, which consists of conductor and insulating layer. The bare wire is tempered and softened, then painted for many times and baked. However, it is not easy to produce products that meet both the standard requirements and customer requirements. It is affected by factors such as raw material quality, process parameters, production equipment, environment, etc. Therefore, the quality characteristics of various enameled wire are different, but they all have four major properties: mechanical properties, chemical properties, electrical properties and thermal properties.

Packing and delivery

1.The mono-filament and its winch are supplied in plates, and then packed and delivered in boxes after proper packaging with Kraft paper and packaging film. The small size disc is fixed by custom foam, and the large size plastic rubber disk or iron disk is fixed by custom wooden frame.

2.The mono-filament and its strand are evenly wound on the wire shaft, the wire arrangement is not pressed, the wire head is fixed, and the outermost side of the wire is kept at a certain distance from the edge of the disk, so as to avoid collision in the course of transportation.

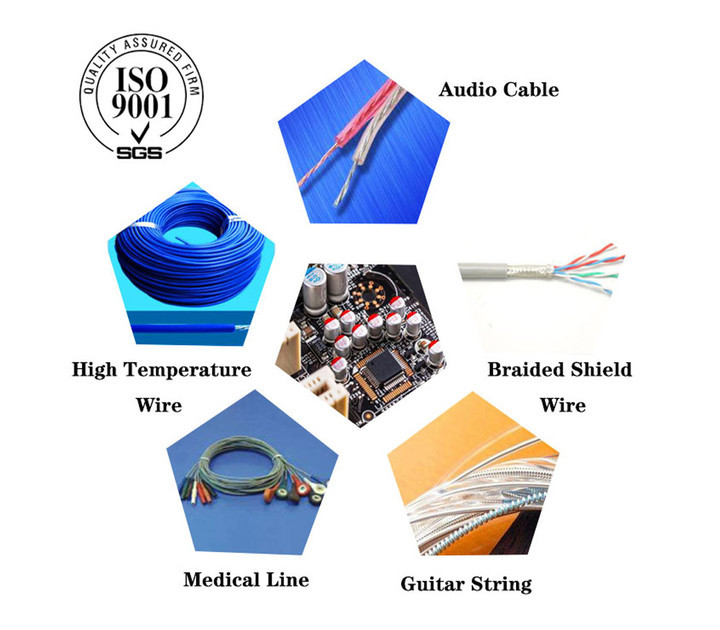

The Application Field of Products

Application: Non-ferrous wire, textile thread, high frequency application, micro cable, aerospace cable, high temperature cable, etc.

Features: High electrical conductivity, high heat resistance, bright and shiny surface, high frequency characteristics, high temperature resistance, corrosion resistance, etc.

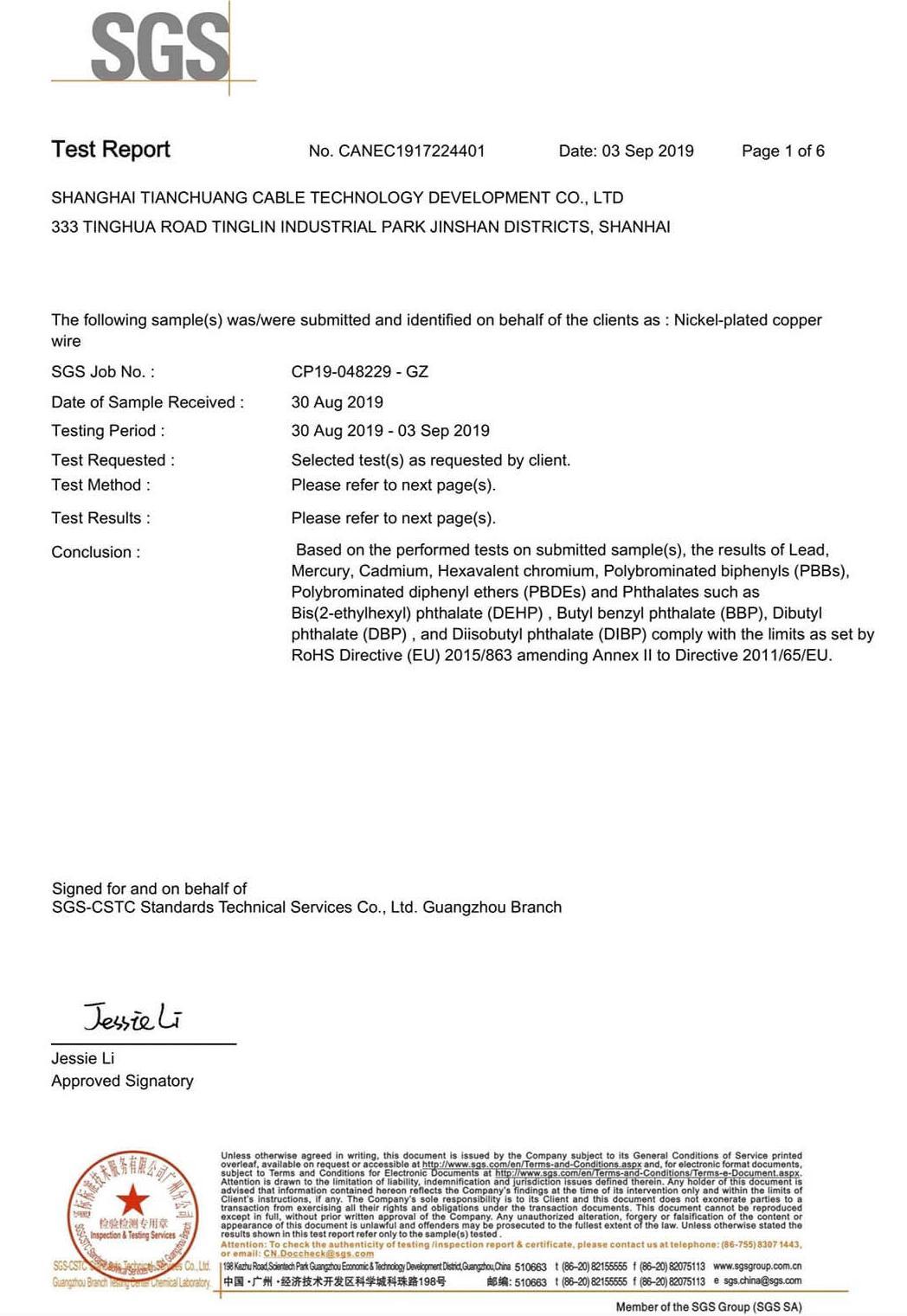

Exhibition and Certification

FAQ

Q1: What are your prices?

A1: Our prices are subject to change depending on supply and other market factors.

Q2: What is the product warranty?

A2: We warranty our materials and workmanship. Our commitment is to your satisfaction with our products.

Q3: What kinds of payment methods do you accept?

A3: You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance against the copy of B/L.

Q4: What is the average lead time?

A4: For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

Previous

MESSAGE

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!