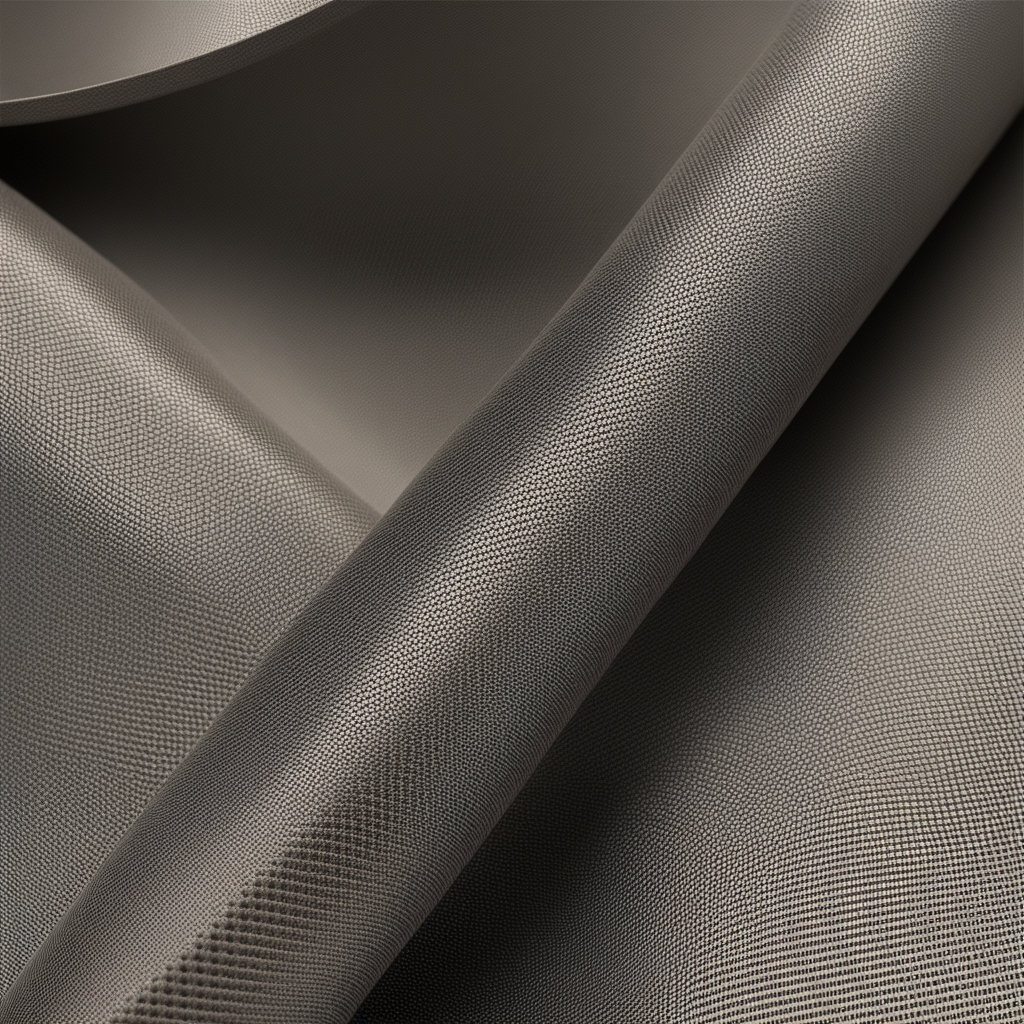

Pure Nickel Mesh

Specialised in alloy melting for more than 20 years, we have complete nickel wire production equipment and mature production process. production process. We produce our own pure nickel wire with excellent performance, using advanced automatic CNC nickel mesh weaving machine. After warping, buckling, weaving to the finished product, and the nickel mesh mesh mesh, flatness and other performance We also check the performance of nickel mesh such as mesh count, flatness, etc. to ensure the zero-defect quality.

Keywords:

Category:

Pure Nickel Mesh

MESSAGE

DESCRIPTION

NICKEL ELECTRODE PRODUCTION

- Nickel wire diameter: 0.03mm~6.0mm

- Nickel purity: >99.5%

- The tolerance of wire diameter can be controlled within 0.002mm

Product specification:

- Material: nickel N6 (in accordance with GB5235)

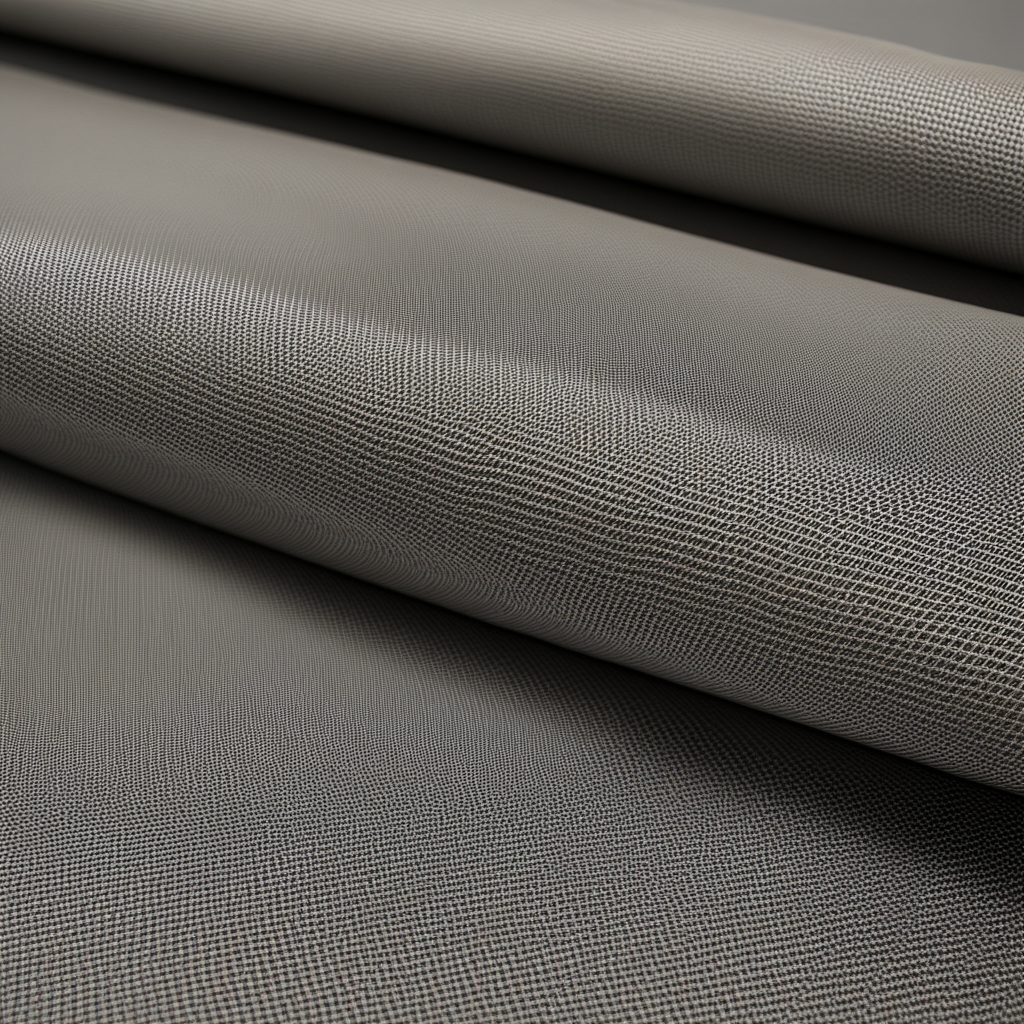

- Product specifications: conventional products 46 mesh * 0.19mm / 46 mesh * 0.25mm/ 60mesh*0.25mm

- Weaving method: plain weave, twill weave

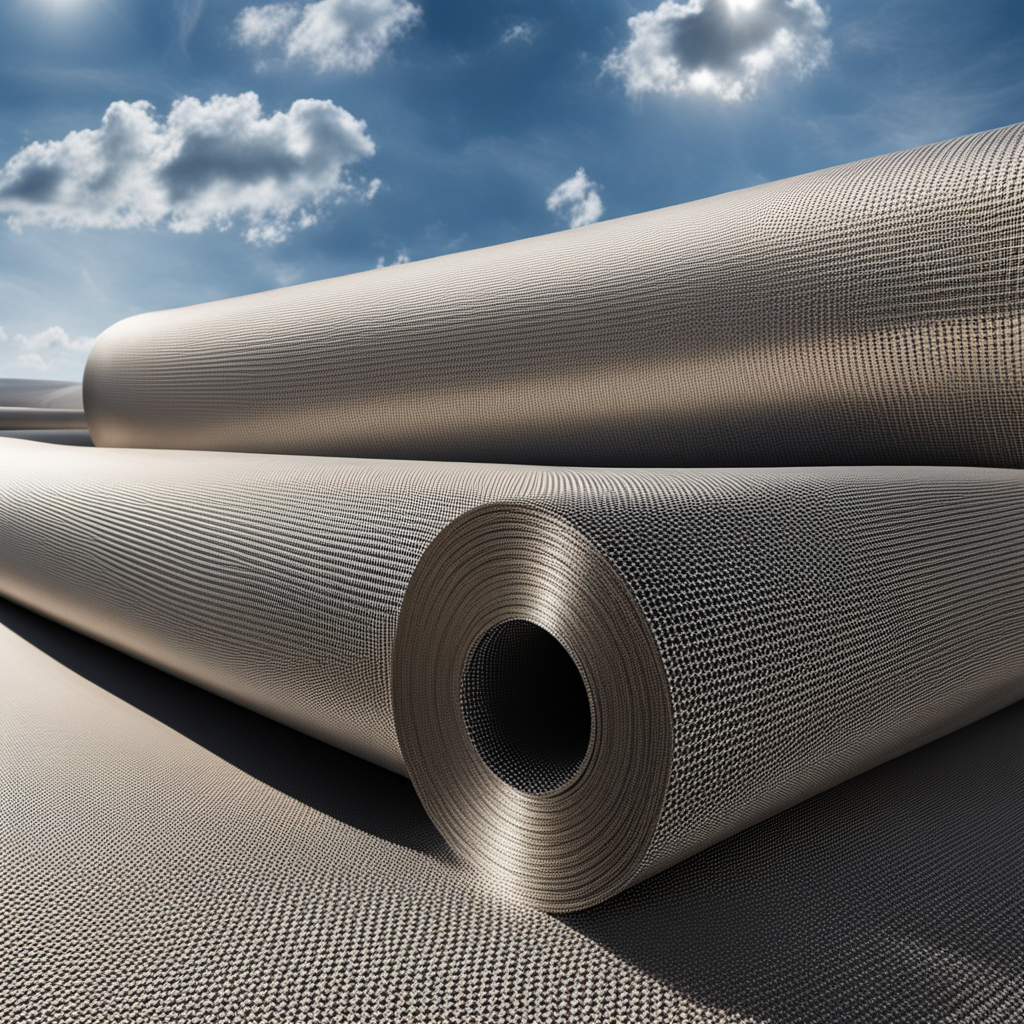

- Finished product size: ≤2.5m, round or square.

- Support other size and mesh (below 200 mesh) customised products

Product Performance:

- Ni Purity: >99.5%

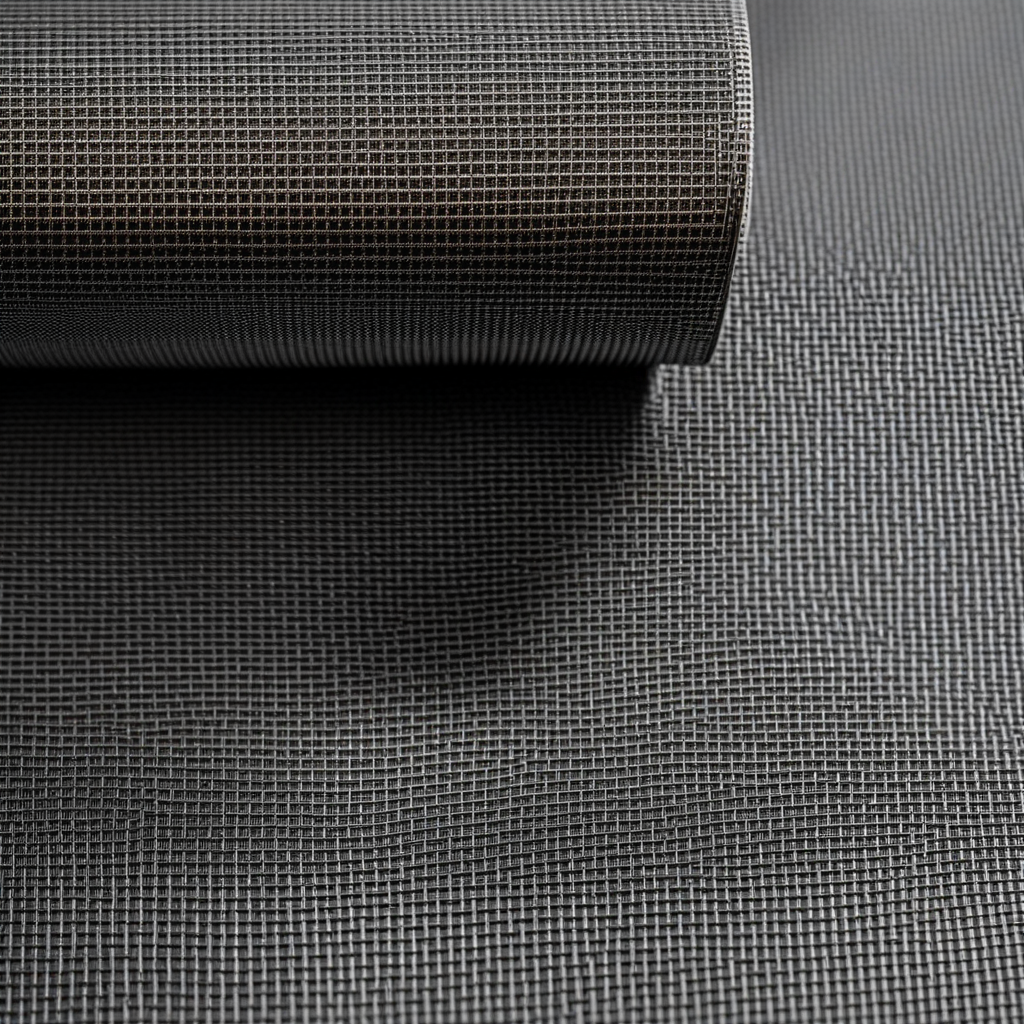

- Mesh size and mesh uniformity: conform to GB/T 17492

- Allowable number of major defects: zero defects (holes, cracks, half cut weft, sparse channel, jumping wire, weft/warp wire loose line, warp wire sparse channel)

- Maximum deviation of the overall size: ± 0.5 per cent

- Nickel mesh flatness: unevenness <5mm/2.5m mesh surface

We can produce pure nickel mesh below,

Square Nickel Mesh

1000*950mm/piece

Mesh: 46

Wire diameter: 0.25mm

Weaving method: twill weaving

Round nickel wire mesh

φ100mm/piece

Mesh: 46

Wire diameter: 0.25mm

Weaving method: Twill weaving

Round nickel wire mesh

φ199mm/piece

Mesh: 46

Wire diameter: 0.25mm

Weaving method: Twill weave

Square nickel wire mesh

300*300mm/piece

Mesh: 46

Wire diameter: 0.25mm

Weaving method: twill weave

Round nickel wire mesh

φ813mm/sheet

Mesh: 46

Wire diameter: 0.25mm

Weaving method: Twill weave

Square nickel wire mesh

1900*1900mm/sheet

Mesh: 60

Wire diameter: 0.25mm

Weaving method: Twill weaving

Square nickel wire mesh

70*70mm/sheet

Mesh: 30

Wire diameter: 0.30mm

Weaving method: plain weave

Nickel wire self-production capacity:

We have 2 sets of 1000kg vacuum melting furnace, 6 sets of 500kg vacuum melting furnace, 3 sets of 100kg melting furnace, 450 sets of wire drawing machine, and 150 sets of annealing furnace. Achieve 0.19mm, 0.25mm pure nickel wire with a capacity of 30 tons/day.

Nickel mesh weaving capacity:

We have 100 sets of fully automatic CNC nickel mesh weaving machines, with a daily capacity of 4,000 metres of nickel mesh with a width of 2~2.5 metres. Fibre laser cutting system for nickel mesh coils. Fibre optic laser cutting system can automatically cut the nickel mesh coil, detect defects by visual imaging and weigh automatically, with a daily output of 2,000 sheets of nickel mesh.

Nickel mesh, as a special type of metal grid, possesses unique properties and advantages commonly employed in batteries, electrochemistry, and various applications. Here are some key advantages of pure nickel mesh:

1. Excellent Electrical Conductivity: Nickel is a highly conductive material, imparting superior electrical conductivity to pure nickel mesh, facilitating the conduction of electric current.

2. Strong Corrosion Resistance: Pure nickel exhibits high resistance to corrosion from various chemicals, allowing it to maintain stable performance in harsh environments.

3. Good Oxidation Resistance: Nickel demonstrates good resistance to oxidation, remaining less prone to oxidation in high-temperature or high-humidity conditions, showcasing outstanding performance in specialized applications.

4. High Mechanical Strength: Pure nickel grids typically possess high mechanical strength, capable of withstanding certain levels of tension and pressure, making them suitable for applications demanding strength.

5. Excellent Thermal Conductivity: Nickel boasts good thermal conductivity, enabling pure nickel mesh to play a role in applications requiring effective heat dissipation.

6. Good Ductility: Pure nickel mesh is easily processed into various shapes, suitable for different design requirements.

7. Long Service Life: Due to its corrosion resistance, oxidation resistance, and mechanical strength, pure nickel mesh generally enjoys a longer service life.

Applications of pure nickel mesh are widespread due to its superior performance characteristics.

Here are some common areas where pure nickel mesh finds extensive use:

1. Battery Manufacturing: Pure nickel mesh is commonly used in the manufacturing of batteries, especially in nickel-metal hydride (NiMH) and nickel-cadmium (NiCd) batteries. Its high conductivity, corrosion resistance, and mechanical strength make it an ideal choice for battery electrode materials.

2. Electrochemistry: In electrochemical research, pure nickel mesh serves as electrode material in electrolytic cells and other electrochemical devices, facilitating various reactions.

3. Electronics Industry: Due to its conductivity, pure nickel mesh is employed in the electronics industry as connectors, wires, and components of circuit boards.

4. Petrochemical Industry: The corrosion resistance of pure nickel mesh in corrosive environments makes it suitable for applications in the petrochemical industry, such as filtration, separation, and handling corrosive media.

5. Aerospace: Pure nickel mesh is used in the aerospace industry for components in spacecraft, satellites, and other aviation structures due to its lightweight, high strength, and oxidation resistance.

6. Medical Devices: The hygienic properties and mechanical strength of pure nickel mesh contribute to its increasing use in medical devices, such as medical filters.

7. New Energy Sector: In the field of new energy, pure nickel mesh is employed in the manufacturing of fuel cells and other components for renewable energy devices.

8. Laboratory Research: In scientific laboratories, pure nickel mesh is often used to construct electrochemical experimental setups and other devices requiring conductivity, stability, and corrosion resistance.

Overall, the multifunctionality and superior performance of pure nickel mesh make it crucial in various fields, providing reliable solutions for diverse applications.

Previous

MESSAGE

If you are interested in our product, please leave your email and we will contact you as soon as possible. Thank you!