NEWS

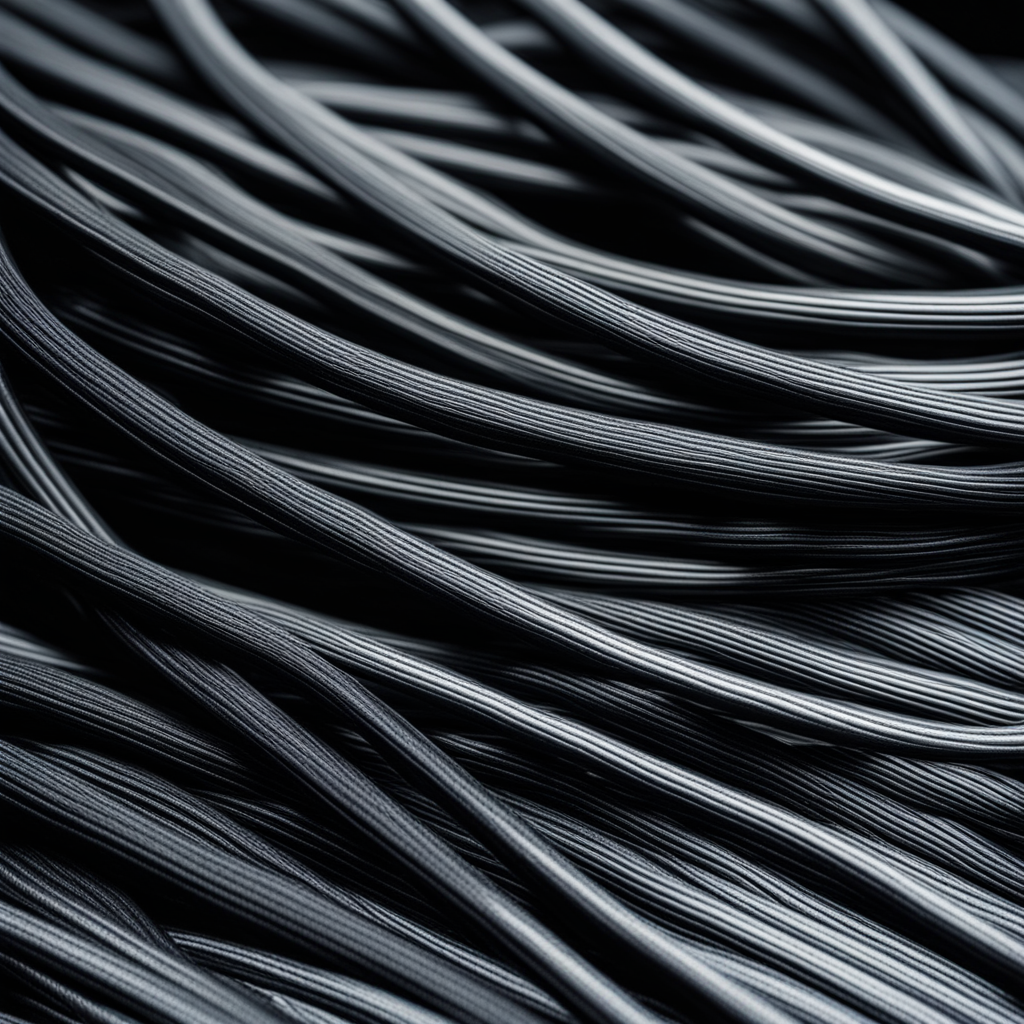

Why is wire drawing done for nickel-plated copper wire

Release time:

2023-11-23 11:24

Nickel-plated copper wire is a wire material where a layer of nickel substance is electroplated or chemically deposited on the surface of copper wire. Compared to pure copper wire, the nickel-plated copper wire has improved corrosion resistance, wear resistance, and hardness, meeting the requirements for subsequent applications in components and extending the lifespan of the components. Before nickel-plating copper wire, to ensure uniformity and compliance with requirements, pre-treatment and wire drawing processes are needed for the copper wire.

Pre-treatment before Nickel-plating Copper Wire

Before nickel-plating copper wire, it is essential to remove surface impurities and dirt from the copper wire to maintain cleanliness for the subsequent nickel-plating process. Subsequently, the copper wire is cleaned with hydrochloric acid solution to remove the oxide film on the surface, facilitating the removal of impurities present on the copper wire surface and laying a foundation for the subsequent nickel-plating process.

Benefits of Wire Drawing for Nickel-plated Copper Wire

1. Smoothing the Surface:

Drawing the wire after nickel plating makes the entire surface of the copper wire smoother, enhancing the uniformity of the entire coating. Typically, the surface color of ordinary nickel-plated copper wire is not very uniform, but wire drawing can result in a smooth and bright appearance.

2. Increased Production Yield and Cost Reduction:

Performing wire drawing on copper wire after nickel plating can increase the production yield and reduce the production cost for the enterprise.

3. Facilitating the Production of Small-diameter Nickel-plated Copper Wire:

Wire drawing is particularly advantageous for the production of small-diameter nickel-plated copper wire. When nickel-plating relatively fine-diameter copper wire directly, there is a higher risk of wire breakage. Wire drawing effectively helps avoid such problems.

News